Introduction

In today's modern world, access to reliable power sources is crucial for various remote locations such as construction sites, mining operations, rural communities, and disaster-stricken areas. In these scenarios, where grid electricity may not be available or may be unreliable, diesel generators emerge as a vital solution to meet the energy needs of these remote locations. This article aims to provide a comprehensive guide to diesel generators for remote locations, covering their features, benefits, applications, maintenance, and important considerations.

Understanding Diesel Generators

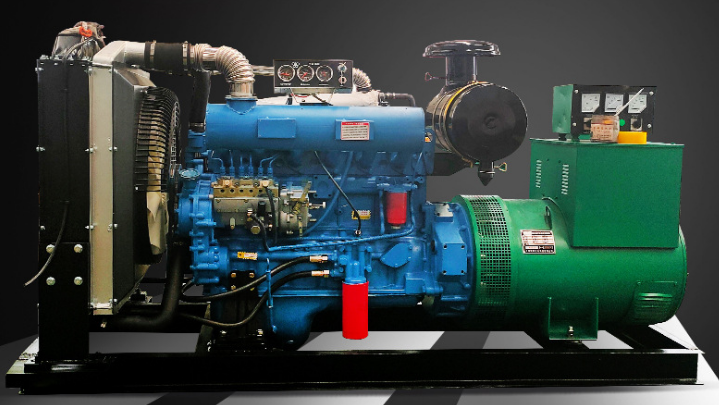

Diesel generators are robust and reliable power generation systems that operate on diesel fuel to produce electricity. They consist of an engine that burns diesel fuel to drive an alternator, which then converts mechanical energy into electrical power. The key components of a diesel generator include the engine, alternator, fuel system, cooling system, exhaust system, and control panel.

One of the primary advantages of diesel generators is their efficiency in converting fuel into electricity. Diesel engines are known for their high energy density, which means they can generate more power with less fuel compared to other types of generators. This makes diesel generators a cost-effective option for powering remote locations where fuel availability may be limited.

Benefits of Diesel Generators for Remote Locations

1. Reliability: Diesel generators are renowned for their reliability and durability, making them ideal for remote locations where continuous power supply is essential. These generators can operate continuously for long hours and can withstand harsh environmental conditions.

2. Fuel Efficiency: Diesel engines are more fuel-efficient than gasoline engines, providing better mileage and longer run times per gallon of fuel. This is particularly advantageous in remote locations where refueling options may be limited.

3. Power Output: Diesel generators are capable of producing high power outputs, making them suitable for running heavy-duty equipment and machinery in remote locations such as construction sites and mining operations.

4. Easy Maintenance: Diesel generators are relatively easy to maintain compared to other types of generators. Routine maintenance tasks such as oil changes, filter replacements, and inspections can help ensure the longevity and performance of the generator.

5. Quick Start-up: Diesel generators can start quickly and reach full capacity within minutes, ensuring a rapid response to power outages or emergencies in remote locations.

Applications of Diesel Generators in Remote Locations

1. Construction Sites: Diesel generators are commonly used to power construction equipment, tools, and temporary facilities at remote construction sites where grid power is not available. They provide the necessary electricity to run heavy machinery, lighting systems, and other essential equipment.

2. Mining Operations: In remote mining sites, diesel generators play a crucial role in providing power for drilling rigs, conveyors, crushers, and other mining machinery. These generators are well-suited for the demanding conditions of mining operations due to their reliability and high power output.

3. Rural Communities: Diesel generators are often used in rural communities and off-grid areas to provide electricity for homes, schools, healthcare facilities, and businesses. https://www.lkpowerplant.com/product/quick-delivery-emergency-standby-power-400kw-silent-type-diesel-generator-set-for-peru/ serve as a reliable source of power for essential services in remote locations where grid connections are impractical or unavailable.

4. Disaster Relief: During natural disasters or emergencies, diesel generators are deployed to provide temporary power supply for rescue operations, temporary shelters, medical facilities, and communication systems in remote areas affected by the disaster. Their portability and reliability make them indispensable in such critical situations.

Maintenance of Diesel Generators in Remote Locations

Proper maintenance is essential to ensure the reliable performance and longevity of diesel generators in remote locations. Here are some key maintenance tasks that should be performed regularly:

1. Regular Inspections: Conduct visual inspections of the generator, engine, fuel system, cooling system, and electrical components to check for any signs of wear, leaks, or damage. Address any issues promptly to prevent further damage.

2. Oil Changes: Regularly change the engine oil and replace the oil filter as recommended by the manufacturer. Clean oil is essential for lubricating the engine components and ensuring smooth operation.

3. Fuel System Maintenance: Keep the fuel tank clean and free of contaminants to prevent fuel system problems. Replace fuel filters and inspect the fuel lines for any leaks or blockages.

4. Cooling System Checks: Monitor the coolant level and quality to prevent overheating of the engine. Ensure that the cooling system components, such as the radiator and hoses, are functioning properly.

5. Battery Maintenance: Check the battery terminals, connections, and electrolyte levels regularly to ensure proper functioning of the generator's starting system. Keep the batteries charged to maintain their performance.

6. Load Testing: Periodically test the generator under load conditions to verify its ability to handle the required power output. This helps identify any issues with the generator's performance and ensures its readiness for operation.

Important Considerations for Diesel Generators in Remote Locations

When selecting a diesel generator for a remote location, several important factors should be taken into consideration to ensure optimal performance and reliability:

1. Power Output: Determine the power requirements of the remote location to select a generator with the appropriate power output capacity. Consider the total load that the generator needs to support, including both essential equipment and potential future expansions.

2. Fuel Efficiency: Choose a diesel generator with high fuel efficiency to minimize fuel consumption and operating costs in remote locations where fuel availability may be limited.

3. Portability: If the generator needs to be moved frequently or deployed to different locations, consider its portability and ease of transportation. Look for generators with compact designs and sturdy handles for easy mobility.

4. Environmental Considerations: Assess the environmental conditions of the remote location, such as temperature extremes, humidity levels, and altitude, to select a generator that can withstand these conditions. Look for generators with weatherproof enclosures and robust construction for durability.

5. Noise Levels: Consider the noise levels produced by the generator, especially in residential or noise-sensitive areas. Choose a generator with soundproofing features or consider installing sound barriers to minimize noise pollution.

6. Remote Monitoring: Opt for generators equipped with remote monitoring and control features that allow real-time monitoring of the generator's performance, fuel levels, and maintenance alerts. Remote monitoring capabilities enhance the efficiency and reliability of the generator in remote locations.

Conclusion

Diesel generators play a vital role in powering remote locations where access to grid electricity is limited or unreliable. Their reliability, fuel efficiency, high power output, and ease of maintenance make them an indispensable energy solution for various applications such as construction sites, mining operations, rural communities, and disaster relief efforts. By understanding the key features, benefits, applications, maintenance requirements, and important considerations of diesel generators for remote locations, stakeholders can make informed decisions to ensure reliable and uninterrupted power supply in these challenging environments.